1- Excessive solder joint: Excessive use of solder paste usually causes a 25% return.

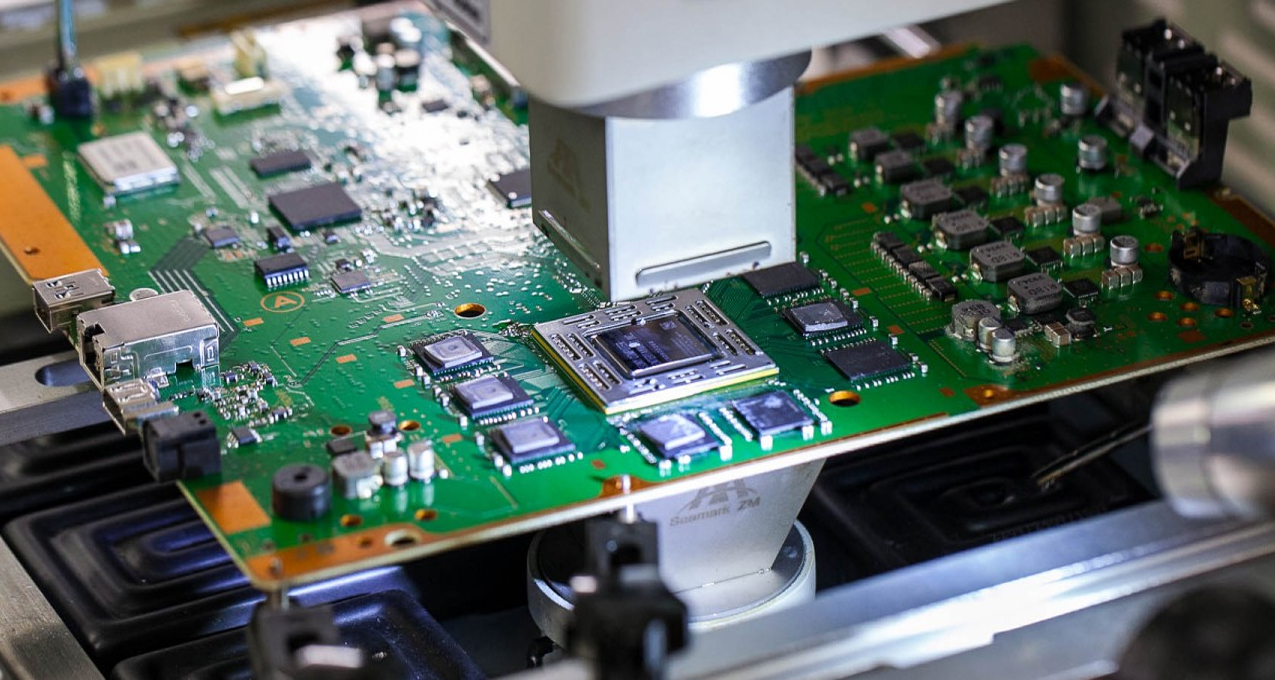

2- Pad damage while removing IC: Repairing damaged pads of a BGA chip is almost impossible and you have to spend a lot of time repairing them.

3- Incorrect BGA orientation: This problem is due to inadequate focus during IC placement as well as insufficient knowledge of the desired IC and the arrangement of its pins.

4- Lack of preparation: Whether or not to use solder paste, choosing the right solder paste stencil, and choosing the right alloys and also removing moisture.

5- Heat damage: The technician must be alert to the amount of heat it gives to the IC, as well as the other components surrounding it.

6- X-ray inspection: The position of the post-solder pins in these types of ICs (BGA) is unknown, but with X-ray inspection machines you can identify problems like excessive voiding and poor placement or alignment.